Laminating and Feeding

Confitech’s laminating and feeding machines are designed to flatten and distribute batch and continuous hard candy for clean delivery to downstream forming lines.

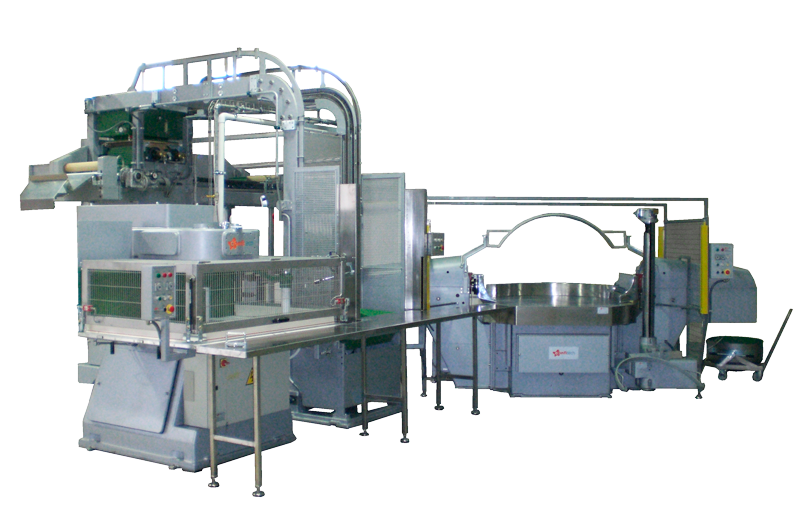

EL.70 and LN.70

Depending on the process design and the number of batch rollers to feed, several options are available. The automatic feeder LN.70 and the newly designed EL.70 allow to feed up to 5 batch rollers from a single loading point, thus eliminating the manual handling of hot and heavy batches. They can be manually fed with batches up to 70 kg, or they can be connected to automatic Kneading Machines IM.70 or Pullers TZ.60 to create a fully automatic transfer from tempering and pulling stations directly to batch rollers without any human intervention, ensuring the automatic feeding of up to 1400 kg of candy mass per hour. Different feeding criteria may be selected to determinate the destination of each batch. That feature is particularly helpful when multiple colour candy or lollipops are processed on the same line.

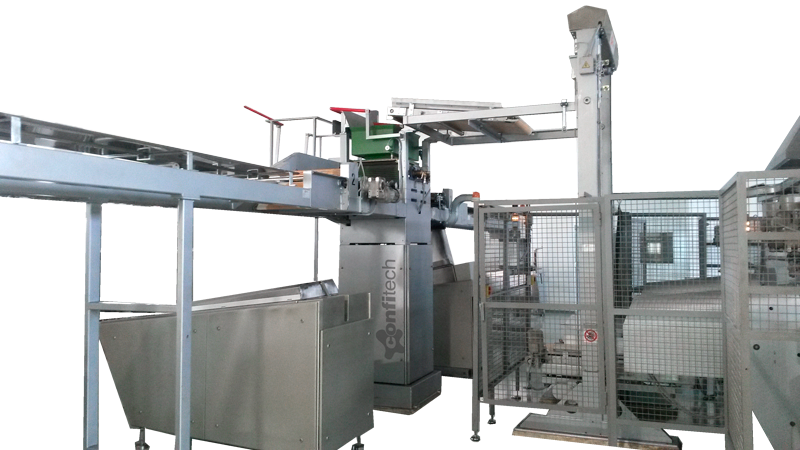

LAM.70

Based on the same principle of the other feeders, the Laminator / Feeder LAM.70 represents a more economical and compact solution for the automation of smaller plants, allowing to feed a single batch roller from a Kneading Machine located at limited distance from the batch roller. A special execution is also available, with an additional distribution belt, to allow feeding two lines with the same machine. On all models, feeding hopper and laminating rollers are Teflon™ coated and their temperature is independently controlled. This is to avoid sticking of the candy mass and to provide consistent feeding to the batch rollers with a mass having correct temperature and plasticity.